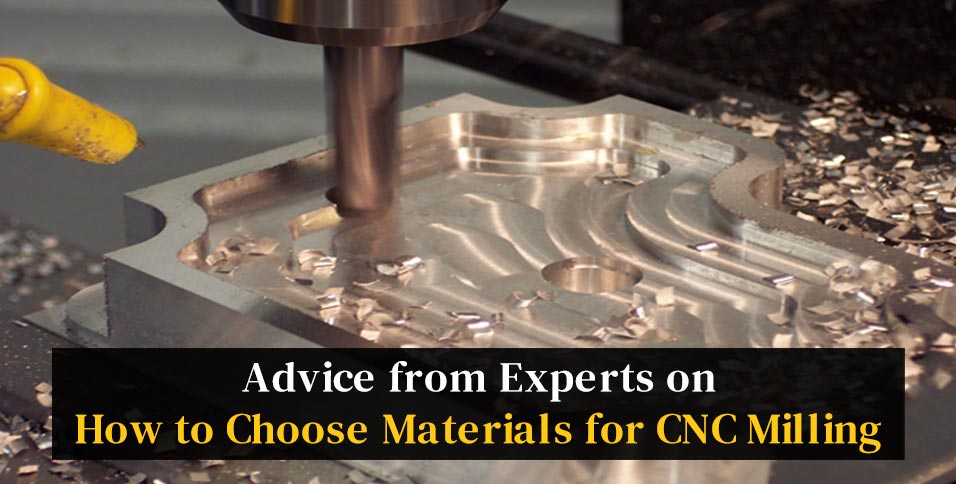

Computers run tools in CNC milling that precisely shape materials. It’s the most modern way to make things. You can make tough shapes very well with this process.

What you use for CNC milling is very important because it determines how well the cutting works and how nice the product looks. Choosing the right material will make the process go more easily, your tools will last longer, and your parts will work better. In this area, following XMAKE’s advice can help you get better results. This is a key step on the way to CNC cutting.

Things to think about when picking out materials for CNC milling

A. Properties of the Material

Before picking out materials for CNC cutting, you should think about what those materials are good at already. When you grind something, the strength of the material tells you how well it can handle the force. Hardness is also important because it changes how fast the cutting tools break and how long the whole process takes. How easy it is to machine and how good the finished product is based on how ductile the material is. When something is ductile, it can change shape when it is pushed without breaking.

B. The result you want

What the finished part is going to be used for is a big factor in the materials that are chosen. To get different effects, you need different kinds of materials. One example of a part that needs to be strong and last a long time is one that will be used in high-stress situations.

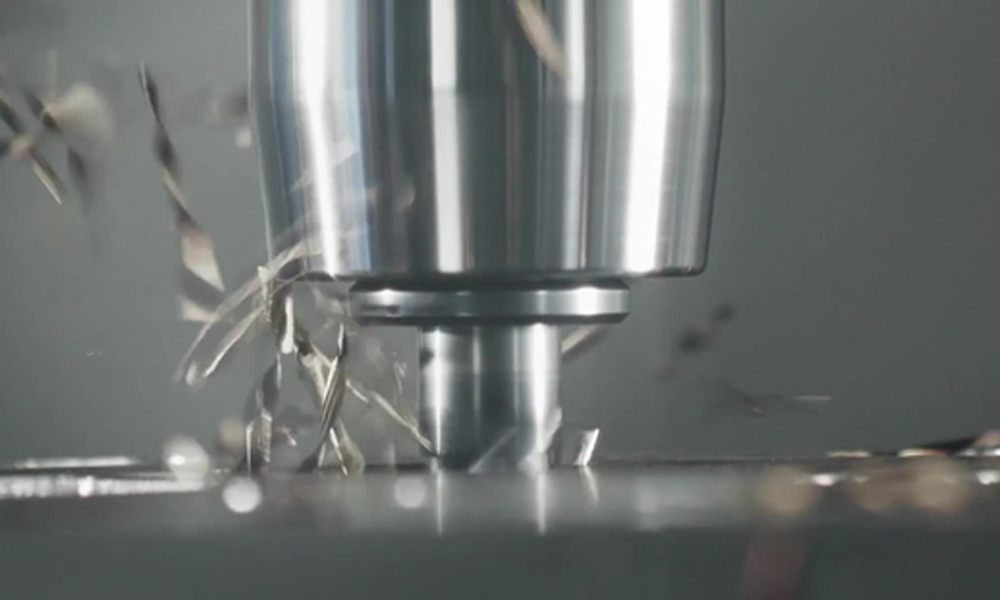

C. The chance of chip formation

When you grind something, it’s also important to think about how likely it is to break into chips. A part may be harder to machine and not as smooth on the outside if it chips because of the way it is made. If you know about this, you can pick materials that will cut more easily and with fewer mistakes.

D. Thoughts on Cost

Lastly, you shouldn’t forget about cost, which is a big deal. What makes the price of the project match the price of the material? How easy is it to get the material? How much does it cost to machine? To get the job done and make money, it’s important to find a good mix between how much the materials cost and how well they are made.

Advice from experts on how to choose materials for CNC milling

A. Types of Materials That Are Often Used in CNC Milling

When you use CNC cutting, you can work with a lot of different materials. Most of the time, they are made of aluminum, steel, brass, or titanium. Each of these items is good for different things because it has its own perks and features.

1. A lot of people like aluminum because it is light and good at moving heat, which makes it great for places where heat needs to be taken away quickly. The business world also likes it because it’s simple to make.

2. Steel is strong and lasts a long time, so it is often used for hard work. It can be changed to fit the job because it comes in many strength levels.

3. Brass is a good metal to work with because it doesn’t rust and is easy to shape. Parts that need to be very accurate and have a smooth finish are often made with this one.

4. Even though titanium is very strong and hard to work with, it is used in medicine and airplanes because it is safe and has a good strength-to-weight ratio.

B. Materials that are suggested for certain uses

The Pro A lot of the time, when experts tell you what things to use, they also explain how it will be done. This makes sure that the economy and function are at their best.

1. Aluminum metal and other materials that keep heat in and move heat slowly are best for high-speed cutting. You can use this tool even though it gets hot when you cut quickly because it won’t damage these materials.

2. Most of the time, things that don’t bend and have smooth sides are best for making straight lines. Iron and some kinds of steel are worse because they are hard to work with and don’t hold together well.

3. To make a prototype, you need materials that are easy to work with and can be made quickly so that the parts can be used. Some materials are picked because they are simple to work with and allow things to be made quickly.

In conclusion

Finally, I can’t stress enough how important it is to pick the right material for CNC cutting. It is a very important part that impacts the cutting process, the reliability of the tools, and the quality of the final result. When picking a material, the main things we talked about—its properties, how well it works with other things, how well it gets rid of heat, and its surface finish—are very important.

About the Author:

Frank Lee, At the helm of XMAKE, Lee directs the vision with expertise honed at HIT with over 16 years in the field, including as a Lean Manufacturing System expert at General Motors and global evaluator, Frank has a proven track record of pioneering improvements across 1000 factories.

Also Read: Expert Recommendations for Material Selection in CNC milling